Technology

Technology

Comburex Srl is developing High pressure Type 4 cylinders made of composite and thermoplastic liner, and type 5 to store gas at high pressure (350 – 1000 bar).

The tanks are composed of a mixture of resin and fibers (composite material) where the resin acts as a binding agent that holds all the fibers together, creating a strong structure. A thermoplastic liner or a special resin is then used to reach hydrogen impermeability.

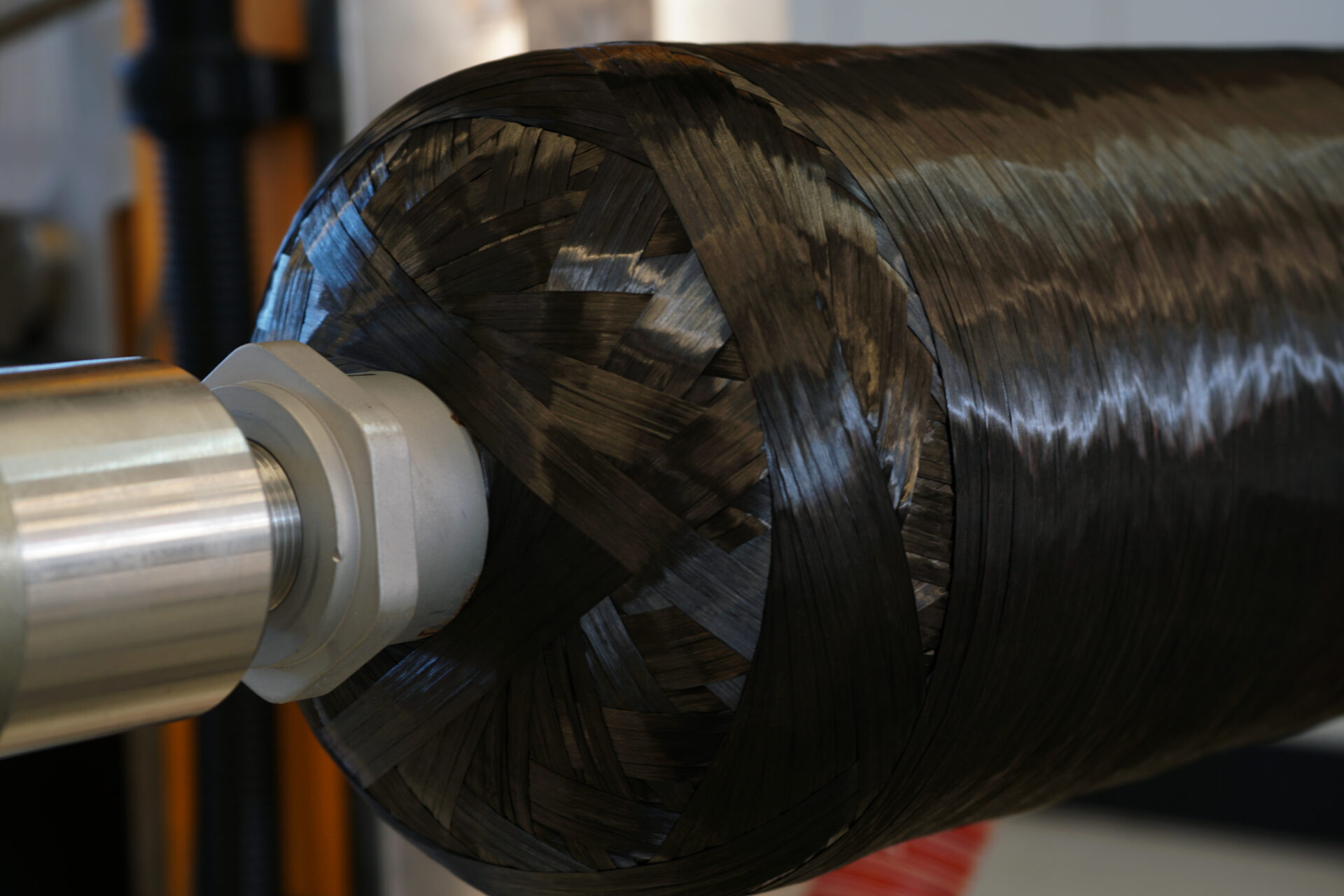

Our cylinders are produced using sophisticated filament winding machines to combine a high level of automation with precise fibre layout.

We use pre-impregnated carbon fiber (Tow-preg) to mechanically optimize quantity of resin and achieve same performance with lower weight. This technology enhances quality control and increase productivity.

Thanks to the high strength-to-weight ratio of carbon fiber We are able to develop light-weight cylinders that can hold high pressures required for hydrogen storage. This wouldn’t be possible with steel, aluminum or glass fiber, already used for lower pressure applications.

- Strong Material

- Mechanical Optimization

- Light Weight

- Higher Pressure